-

A

For Normal

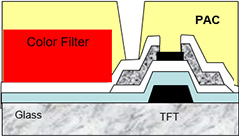

Color Filter -

-

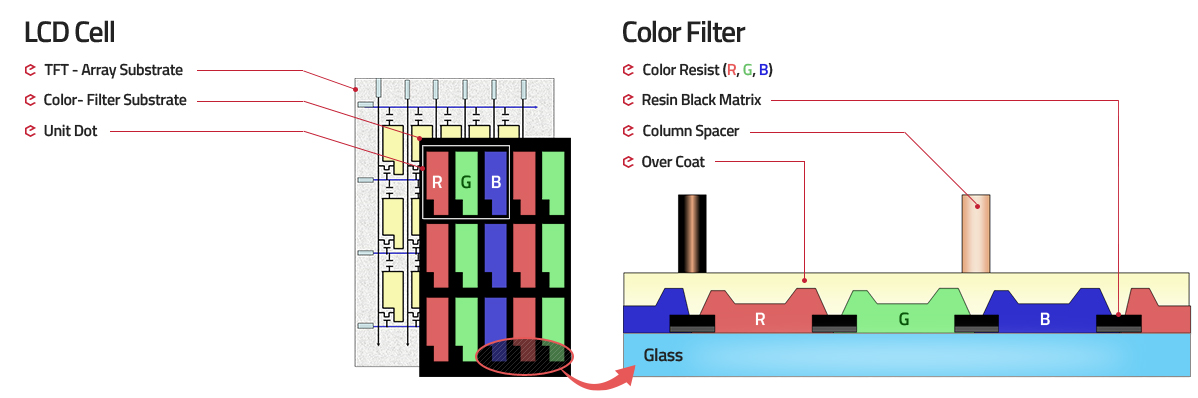

- 1Color Resist (R,G,B)

- This is a photo-radically polymerizable negative type of colorant-dispersed photoresists which can form sub-pixels of a color filter. It is possible to design various colors according to customer's color design. There are high-brightness grade with high transparency, high color reproduction grade with excellent color rendering ability, and high color reproduction/high reliability grade suitable for white OLED color filter, etc. In addition, we are researching and developing color photoresists applying new colorants such as dyes excellent in light resistance/heat resistance.

-

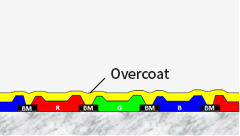

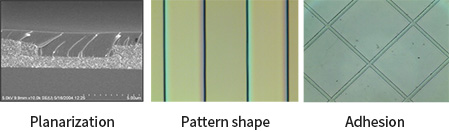

- 2Overcoat (OC)

- It functions as a color filter flattening and protective film. The most common ones are thermosetting OC, of which the advantage is the excellence in transparence, flatness, reliability and adhesion. In addition, there is a photodefinable OC that can be patterned by photolithography, thereby used to form touch panels and various types of transparent insulating layers.

-

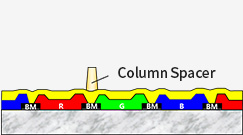

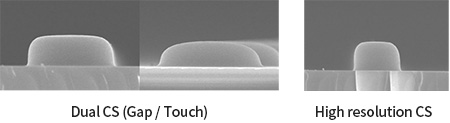

- 3Column Spacer (CS)

- This is a negative type of photoresists that can form a Photo Spacer or Patterned Spacer (PS) that maintains a constant Gap of the LCD Cell. It is a high resolution CS PR that can create high resolution CS, and it can simultaneously form both Gap CS for maintaining normal Cell Gap and Touch CS for supporting Gap when pressing LCD cell by using HTM (Half Tone Mask).

-

- 4Black Matrix (BM)

- It is a Pixel Defining Layer that prevents unintentional Back Light leakage in areas not driven by electrodes, protect from external light entering the TFT area, and blocks the color mixing effect between color filter sub-pixels. It is a customized negative type of black photoresist which can adjust the resistance value, dielectric constant, optical density (OD), size of fine pattern width, etc.

-

-

B

Multi

-Functional

Photoresists -

-

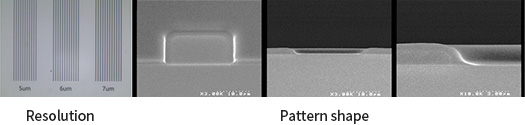

- 1Column spacer(CS)

- This is a negative type of photoresists that can form a Photo Spacer or Patterned Spacer (PS) that maintains a constant Gap of the LCD Cell. It is a high resolution CS PR that can create high resolution CS, and it can simultaneously form both Gap CS for maintaining normal Cell Gap and Touch CS for supporting Gap when pressing LCD cell by using HTM (Half Tone Mask).

-

Product Characteristics

- - Adjustable sensitivity, resolution, T/B-CD, and ΔH

- - Secures outstanding compression recovery rate

- - Secures uniform thickness and coating speed

-

- 2Overcoat(OC)

- It functions as a color filter flattening and protective film. The most common ones are thermosetting OC, of which the advantage is the excellence in transparence, flatness, reliability and adhesion. In addition, there is a photodefinable OC that can be patterned by photolithography, thereby used to form touch panels and various types of transparent insulating layers.

-

Product Characteristics

- - Enables development of photo-curable and thermosetting OC

- - Able to adjust flatness

- - Secures chemical resistance, high permeability, and adhesion

-

- 3Low-Temperature Photo-Curing Overcoat(OC)

- The overcoat protects color filter of normal overcoats curable in temperature over 200 ℃ and its flattening function is cured in temperature below 100 ℃ to show the equivalent performance. Especially, it is applied in OLED displays packaged with light emitting color filter vulnerable to heat resistance due to low setting temperature.

-

Product Characteristics

- - Secures curing in temperature over 85 ℃

- - Secures flatness, chemical resistance, high permeability, and adhesion

- - Expresses fine patterns and adjusts pattern shapes

-

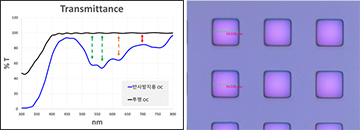

- 4Anti-Reflective Overcoat(OC)

- It uses photo-process to make OC layer replace light amount control function of the polarizing plate, which is used to prevent external light reflection in existing displays. It keeps the existing OC’s flattening and patterning functions and protects the color resist layer at the same time.

-

Product Characteristics

- - Controls transmittance spectrum, color, and reflectance

- - Secures flatness, light stability, chemical resistance, high permeability, and adhesion

- - Expresses fine patterns and adjusts pattern shapes

-

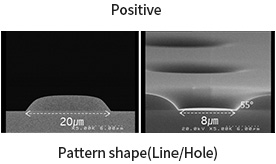

- 5Organic Insulator (PAC)

- The photoresist material acts as flattener, protective film, and insulating film in COA or COT panel and it forms via channel that connects electrodes. It supports positive-type and negative-type products depending on process and it also includes products with excellent flatness and products with excellent resolution.

-

Product Characteristics

- - Enables low dielectric constant

- - Secures high heat resistance, chemical resistance, and adhesion

- - Expresses fine patterns and adjusts pattern shapes

-

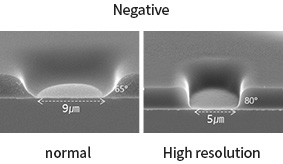

- 6Photosensitive Polyimide (PSPI)

- The polyimide resin-based photoresist material shows excellent thermal, chemical, and mechanical stability to prevent degradation of brightness and pixels in OLED. It has strengths in high-resolution patterning and outstanding reliability.

-

Product Characteristics

- - Highly-reliable material with low out-gas and low moisture absorption

- - Secures high thermal resistance, chemical resistance, dielectric property, and mechanical property

- - Expresses fine patterns and adjusts pattern shapes

-

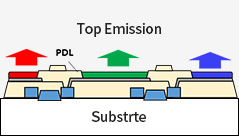

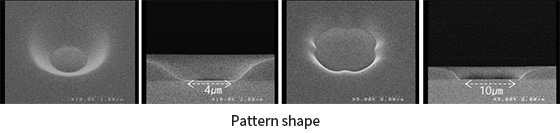

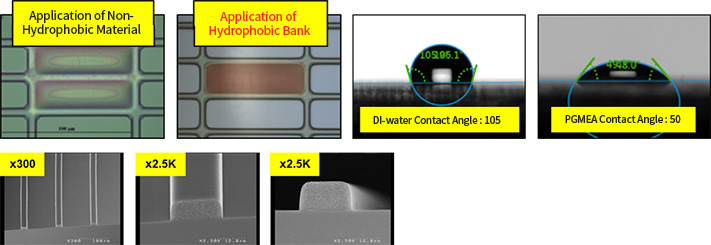

- 7Hydrophobic Bank(PDL, Transparent/Black)

- It forms hydrophobic bank pattern and enables jetting in one pixel to prevent the wet ink from overflowing to adjacent pixel after bank patterning and ink jetting.

-

Product Characteristics

- - Excellent hydrophobic property

- - Low temperature curable, thermal resistance, and chemical resistance

- - Expresses fine patterns and adjusts pattern shapes

-